automatic grinder pump

Photo by Charlotte May on pexels

Photo by Charlotte May on pexels

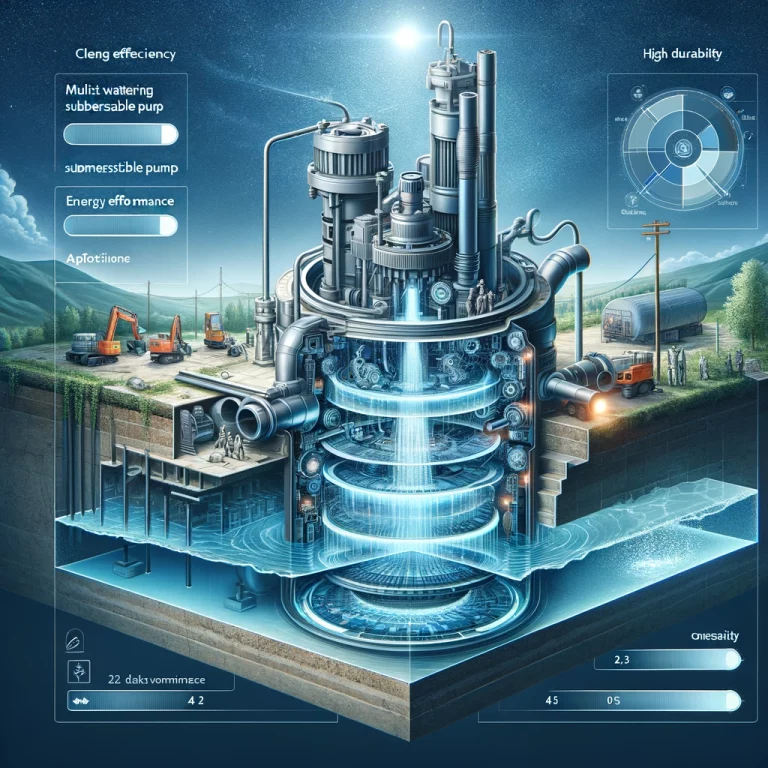

Understanding Grinder Pumps

Grinder pumps are an essential component in various industries and application needs, offering a wide range of options and availability to meet different requirements. Brands like Pentair provide a comprehensive line of grinder pump systems, catering to the sizing and configuration support required for optimal performance. These home products play a significant role in water supply and wastewater management. A white paper by Pentair explains the significance of grinder pumps and their series, highlighting their advantages in preventing clogs and ensuring efficient operations. With a variety of models and options, grinder pumps have evolved to meet the specific needs of different industries and application scenarios.

The Basics of Grinder Pumps

Grinder pumps are an essential part of modern sewer systems. They utilize cutting-edge technology to solve a common problem faced by many home, business, and utility owners – clogging in wastewater pipes. These powerful pumps are designed to grind and shred any solids that may enter the sewer system, including rags, trash, and other debris. The V series grinder pumps, known for their exceptional cutter technology, have become a popular choice due to their ability to handle tough clogs. With features like plenty of cutting heads, these pumps effectively process solids, preventing any blockages from occurring in the sewer lines.

Grinder pumps play a crucial role in keeping our sewer systems running smoothly. One well-known brand that excels in this field is Pentair Grinder Pumps. Their SLRWD models, in particular, offer advanced features that ensure optimal performance. These pumps are specifically designed to handle the challenges posed by the wastewater environment. With their durable construction and efficient cutting technology, Pentair grinder pumps are capable of tackling the toughest of clogs. Whether it’s in residential, commercial, or utility applications, these pumps provide reliable and effective solutions for any sewer system.

Educational Insights into Grinder Pumps

Grinder pumps play an essential role in tackling wastewater challenges, and gaining educational insights into them can greatly benefit businesses and professionals in the industry. By understanding the working principles and application scope of these pumps, individuals can take action with confidence and make informed decisions for their wastewater pump installation projects. Educational resources, such as Pentair Academy, provide a breeze of valuable information, offering access to tools, programs, and informative materials. Whether it is through comprehensive training courses, insightful infographics, or direct consultations with customer service representatives, businesses can rely on these educational initiatives to enhance their knowledge on grinder pump technology solutions and overcome debris and wipes-related challenges.

In the business world, having reliable partners and staying updated with the latest information are crucial. For professionals involved in grinder pump systems, educational insights can prove to be invaluable assets. By partnering with reputable brands and leveraging their educational programs, individuals can stay at the forefront of cutting-edge industry knowledge. These programs often cover a wide range of topics, including installation techniques, troubleshooting common issues, and the maintenance and care of grinder pump units. With the resources and expertise provided by these programs, businesses can confidently navigate the complex world of wastewater pump applications and ensure the smooth operation of their systems.

Comprehensive Look at Grinder Pump Units

In our comprehensive look at grinder pump units, we will delve into the various aspects and features of these indispensable devices. From the basics of how grinder pumps operate to the educational insights into their functionality, we will take you on a journey to understand these cutting-edge sewer solutions. We will explore different types of grinder pump systems and tactics to optimize their performance. Additionally, we will examine the key features of prominent grinder pump models, such as the Pentair grinder pumps. With their ability to efficiently cut and macerate household waste, grinder pumps play a vital role in preventing costly issues in sewer systems and pump stations. Join us as we dive deeper into the materials, size, applications, and performance of grinder pump units, providing you with the necessary product knowledge to make informed decisions. Whether you’re in need of a demo or looking for convenient trainings, we’ve got you covered in this comprehensive guide.

Effluent Sewage Ejector Grinder: A Closer Look

Effluent sewage ejector grinders are a vital piece of equipment in many sewage systems. These grinders are known for their ability to handle tough solid waste and prevent clogging in the system. One of the key features of these grinders is their tri-slice cutter technology, which ensures efficient cutting and grinding of waste. This not only reduces the risk of blockages but also extends the lifespan of the grinder. Moreover, these grinders are equipped with heat dissipation mechanisms that prevent overheating, ensuring reliable and continuous operation. They are designed to be user-friendly, with easy-to-use switches and dialers that allow homeowners to monitor and control the grinder system effortlessly. With various models available, each with its own set of specifications and cuts, customers can choose the best fit for their specific needs. In addition, the manufacturer provides a comprehensive spec sheet for each model, providing detailed information on the grinder’s capabilities and performance.

Effluent sewage ejector grinders are a cost-effective solution for residential and commercial applications. Unlike traditional grinders, which require frequent oil changes and maintenance, these grinders minimize maintenance costs by utilizing oil-free designs. This not only saves money but also reduces the environmental impact. Another advantage of these grinders is their high amp circuit protection. They are equipped with alarms and switches that alert users to potential issues, such as overload or blockages, ensuring the safety and smooth operation of the system. The grinders are also designed for easy installation, with pre-assembled systems available for hassle-free setup. With their robust construction and durable materials, these grinders can withstand heavy use and provide reliable service for years to come. For more information on these effluent sewage ejector grinders and other grinder pump systems, visit the manufacturer’s home page products.

Examination of Cast Iron Thermoplastic Grinder Pumps

Examination of Cast Iron Thermoplastic Grinder Pumps:

Cast iron thermoplastic grinder pumps are a popular choice for many sewage and effluent disposal systems. These pumps are known for their durability and reliability, making them a valuable asset for homeowners and businesses alike. One key feature of cast iron thermoplastic grinder pumps is their ability to handle solid waste and sewage. Equipped with a powerful cutter system, these pumps can effectively grind down and break up particles, preventing clogs and ensuring efficient operation. With a variety of basin accessories and pipe accessories available, these pumps can be easily integrated into existing sump and sewage systems. Whether it’s residential or commercial, cast iron thermoplastic grinder pumps offer a dependable solution to any sewage-related problem.

When it comes to service and maintenance, cast iron thermoplastic grinder pumps are designed with convenience in mind. Many models come with battery backup options, providing extra reliability during power outages. Additionally, utility and switch control systems allow for easy monitoring and operation of the pumps. With the support of various valves, pipe accessories, and poly basins, these grinder pumps offer a comprehensive solution for sewage and effluent disposal. By investing in cast iron thermoplastic grinder pumps, homeowners and businesses can ensure proper sewage management and a worry-free system.

Unpacking Grinder Pump Systems

When it comes to unpacking grinder pump systems, there are several essential components that should be included. These components include alarms, valves, and various accessories such as fiberglass catch basins, extensions, and junction boxes. Additionally, foam basin packages and foam basins are crucial for optimal pump performance. It is also important to have access to a range of repair parts and pump parts to ensure the longevity of the system. Finding a reliable manufacturer is key in order to obtain a high-quality pump. Whether it’s a 2hp manual pump or a more advanced control panel, having access to the necessary components is vital for the successful operation of the grinder pump system. Contact a trusted supplier or browse through various online marketplaces to find the best options available.

Tactics to Optimize Grinder Pump Systems

To optimize grinder pump systems, there are several tactics that can be employed. First, it is important to ensure that the system is properly phased and balanced. This means that all components, including the discharge pipe and power cord, are correctly installed and working together seamlessly. It is also crucial to regularly check and maintain the grinder pump itself, as well as any related products or accessories. This includes keeping an eye on the SKU number of the pump system, as well as reaching out to customer service for any inquiries or troubleshooting needs. By staying informed and proactive, any potential issues can be addressed promptly and efficiently.

Another tactic to optimize grinder pump systems is to stay up-to-date with industry news and advancements. This can be achieved by regularly checking relevant websites, such as the Frankline Electric website or the Comstar.biz pump store. By staying informed, pump owners can learn about new products or technologies that may enhance the performance of their grinder pumps. Additionally, by reading customer reviews and testimonials, individuals can gain insight into the experiences of others and make informed decisions when it comes to selecting and optimizing their pump systems. Overall, staying connected and knowledgeable is key to maximizing the functionality and efficiency of grinder pumps.

Exploring Different Types of Grinder Pump Systems

Grinder pumps are an essential tool for the efficient transfer of sewage waste in various plumbing systems. There are different types of grinder pumps available, including the series grinder pumps. These pumps offer an overview of the different head conditions and performance requirements that they can handle. They come in different sizes and specifications to suit different applications. One of the key benefits of series grinder pumps is their grinding capability, thanks to their powerful motor and durable brass impeller. This allows them to tackle tough waste materials and prevent downtime due to clogging or blockages. With reliable start components and an easy-to-use interface, series grinder pumps are a reliable choice for any sewage waste transfer job.

To ensure the best performance, it is important to understand the different types of grinder pump systems available in the market. Each type has its own unique features and advantages that make it suitable for specific applications. Some grinder pump systems are designed for residential use, while others are better suited for commercial or industrial settings. By exploring the different types, you can find a pump that is tailored to meet your specific needs and requirements. Factors such as pump size, specifications, and motor power should be considered to ensure optimal performance. Additionally, identifying the benefits that each type of pump offers, such as efficient grinding capabilities, durable construction, and reliable performance, can help you make an informed decision. By examining the different types of grinder pump systems, you can choose the right one to face the challenges of your sewage waste transfer job head-on.

Grinder Pump Control Units

Grinder pump control units play a crucial role in the efficient operation of grinder pump systems. These control units have a variety of essential features that ensure smooth functioning and prevent any potential damage. The control panels are equipped with overload protection and capacitor kits to handle the demands of heavy-duty operation. They also have brass cutting clearances for accurate cutting and corrosion resistance, ensuring long-term durability. Additionally, these control units are designed to withstand extreme temperatures, with specific models like the 950266||cfsw| and 950267||cfst| offering temperature protection up to 20 degrees. With their robust specifications and approval for safe usage, grinder pump control units are an indispensable component in maintaining optimal performance and longevity of grinder pump systems.

The Functionality of Grinder Pump Control Panels

Grinder pump control panels play a crucial role in the functionality of grinder pump systems. These panels are equipped with a variety of features and accessories to ensure effective operation. Key components include control floats, float switches, adapter harnesses, and cord adapters. The control panel acts as the brain of the system, monitoring and controlling the pump’s performance to maintain optimum functionality. Additionally, the panels are designed to support various grinder pump models, such as the 1-1/4″ series grinder pumps. These control panels often come with warranties, providing peace of mind to users. To learn more about the versatility and capabilities of these control panels, refer to market brochures, case studies, and downloadable manuals and spec sheets for grinder pump accessories.

Grinder pump control panels are designed for efficient operation and easy accessibility. They are equipped with features like capacitors, leg kits, and adapter kits to ensure seamless integration with the grinder pump system. The control panels are often compact and durable, enclosed in a sturdy case to protect against external elements. The control float and float switch provide reliable control over the pump’s operation, preventing overflow and damage to the system. Users can also find additional accessories like adapter harnesses and adapter cords to facilitate installation and compatibility. These control panels are backed by industry-leading warranties, ensuring long-term performance and customer satisfaction. For more details on specific models and their functionalities, refer to the comprehensive range of downloads, brochures, and case studies available for grinder pump control panels.

Essential Features of Grinder Pump Control Boards

Grinder pump control boards come with essential features that streamline the ordering process for customers. These control boards provide a convenient and user-friendly interface for customers to access and update their order information. Customers can easily track their orders and view their shipping details, such as the shipping policy, area surcharges, and estimated shipping time. Additionally, the control boards offer a pickup option for customers who prefer to pick up their items in person. This includes the ability to select a pickup location, answer any pickup related questions, and complete the checkout process for a pickup order. With these features, grinder pump control boards provide a seamless ordering experience for customers.

In addition to facilitating the ordering process, grinder pump control boards also offer support materials for customers. These support materials include product manuals, FAQs, and troubleshooting guides to assist customers with any inquiries they may have. Customers can access these materials directly through the control board interface, making it easy to find answers to common questions or issues. The control boards also provide rating and review options for customers to share their feedback on purchased products, helping other customers make informed decisions. With a wealth of resources at their fingertips, customers can rely on these control boards to provide the necessary support for their grinder pump needs.

Prominent Grinder Pump Models

Prominent Grinder Pump Models are essential for efficient sewage and wastewater removal. One notable model worth exploring is the Pentair Grinder Pump. This pump boasts a range of impressive features, including a powerful motor and robust construction. Whether it’s small-scale residential use or large-scale commercial applications, the Pentair Grinder Pump delivers outstanding performance. It is widely available in various locations across Illinois, including Bolingbrook. To check pickup availability and change pickup locations, customers can visit the product page on the manufacturer’s site. Additionally, customers can easily add the pump and its accessories to their cart and proceed with the order. Both online and paper check payment options are available, ensuring a seamless purchasing experience. To ensure timely communication, customers are required to provide their name, mobile phone number, and email address during the checkout process.

Features of Pentair Grinder Pumps

Pentair Grinder Pumps offer a variety of features that make them a reliable choice for sewage and wastewater applications. With their rugged construction and powerful performance, these pumps ensure efficient and effective wastewater management. One notable feature is the availability of convenient check discounts, allowing customers to save on their purchase. By simply checking for discounts at their local supplier or online store, individuals can find this valuable information and save on their purchase. Additionally, Pentair has established strong partnerships with local manufacturers, making it easier for customers to access their products. Plus, with flexible shipping options, customers can choose the most cost-effective method for their needs. Whether it’s ground curbside or via semi-truck, the details regarding pickup instructions and lift gate availability are provided, allowing customers to tailor their order to their specific requirements.

Pentair Grinder Pumps also prioritize customer convenience by offering a variety of payment methods. Whether using Apple Pay, credit cards, or other popular options, customers have the flexibility to choose the payment method that best suits them. This ease of payment ensures a smooth transaction process, helping customers to save time and energy. Furthermore, Pentair understands the importance of packaging and providing clear instructions. With their attention to detail, customers can rest assured that their grinder pump will be securely packaged and arrive safely. Plus, for even greater savings, customers have the option to pick up their orders, eliminating shipping costs altogether. Whether purchasing online or directly from a local supplier, Pentair Grinder Pumps cater to the diverse needs of customers, offering convenience, savings, and reliable performance in one package.

Photo by Tim Douglas on pexels

Photo by Tim Douglas on pexels

Conclusion

Grinder pumps are essential for efficiently managing sewage and wastewater in various settings such as residential buildings, hotels, restaurants, and bars. These powerful devices, equipped with sharp blades, effectively grind solid waste particles into slurry, allowing them to flow easily through drains and sewage systems. Grinder pumps offer a reliable solution to the problem of sluggish or clogged drains caused by the improper disposal of items such as dishware, garnishes, and other solid waste. With features like control panels and financing options through platforms like Paypal, property owners can ensure smooth operation and easy access to grinder pump systems. By understanding the basics, exploring different types, and considering prominent models like Pentair grinder pumps, individuals can make informed decisions to meet their specific sewage disposal needs.

FAQ

What is an automatic grinder pump?

An automatic grinder pump is a type of sewage pumping system specifically designed to handle wastewater and solid waste in residential and commercial buildings. It automatically grinds the solid waste into smaller particles before pumping it through the sewer lines.

How does an automatic grinder pump work?

When wastewater enters the grinder pump, it activates a sensor that starts the motor. The motor spins a blade or impeller that grinds the solid waste into smaller pieces. The waste is then pumped through the sewer lines to a main sewer or septic tank.

What are the advantages of using an automatic grinder pump?

Automatic grinder pumps are highly efficient in handling wastewater and solid waste. They can handle larger solids without clogging and are ideal for low-pressure sewer systems. They also eliminate the need for manual intervention or maintenance.

Can an automatic grinder pump handle all types of waste?

Automatic grinder pumps are designed to handle solid waste commonly found in sewage systems, such as toilet paper, feminine hygiene products, and food waste. However, they cannot handle non-biodegradable items like plastics, metals, or chemicals.

Are automatic grinder pumps noisy?

While grinder pumps do make some noise during operation, modern models are designed to minimize noise. The noise level is typically comparable to that of a running dishwasher or washing machine.

Do automatic grinder pumps require regular maintenance?

Automatic grinder pumps require minimal maintenance. However, it is recommended to have them inspected and serviced by a professional at least once a year to ensure optimal performance and prevent any potential issues.

Are automatic grinder pumps energy-efficient?

Yes, automatic grinder pumps are generally energy-efficient. They are designed to operate only when wastewater enters the system, reducing energy consumption compared to traditional sewage pumps that run continuously.

Can an automatic grinder pump be installed in any property?

Automatic grinder pumps can be installed in most properties, including residential homes, commercial buildings, and even remote locations. However, it is important to consult with a professional to determine if your property’s sewer system is suitable for a grinder pump installation.

How long do automatic grinder pumps last?

The lifespan of an automatic grinder pump can vary depending on its usage and maintenance. On average, a well-maintained pump can last between 10 to 15 years. However, regular inspections and timely repairs can significantly extend its lifespan.

Are automatic grinder pumps environmentally friendly?

Automatic grinder pumps help prevent sewage backups and ensure proper wastewater management, which is environmentally beneficial. However, it is important to use the system responsibly and avoid disposing of non-biodegradable items into the sewer system to maintain its environmental benefits.