Advantages of using Multi-Stage HOMA submersible pumps

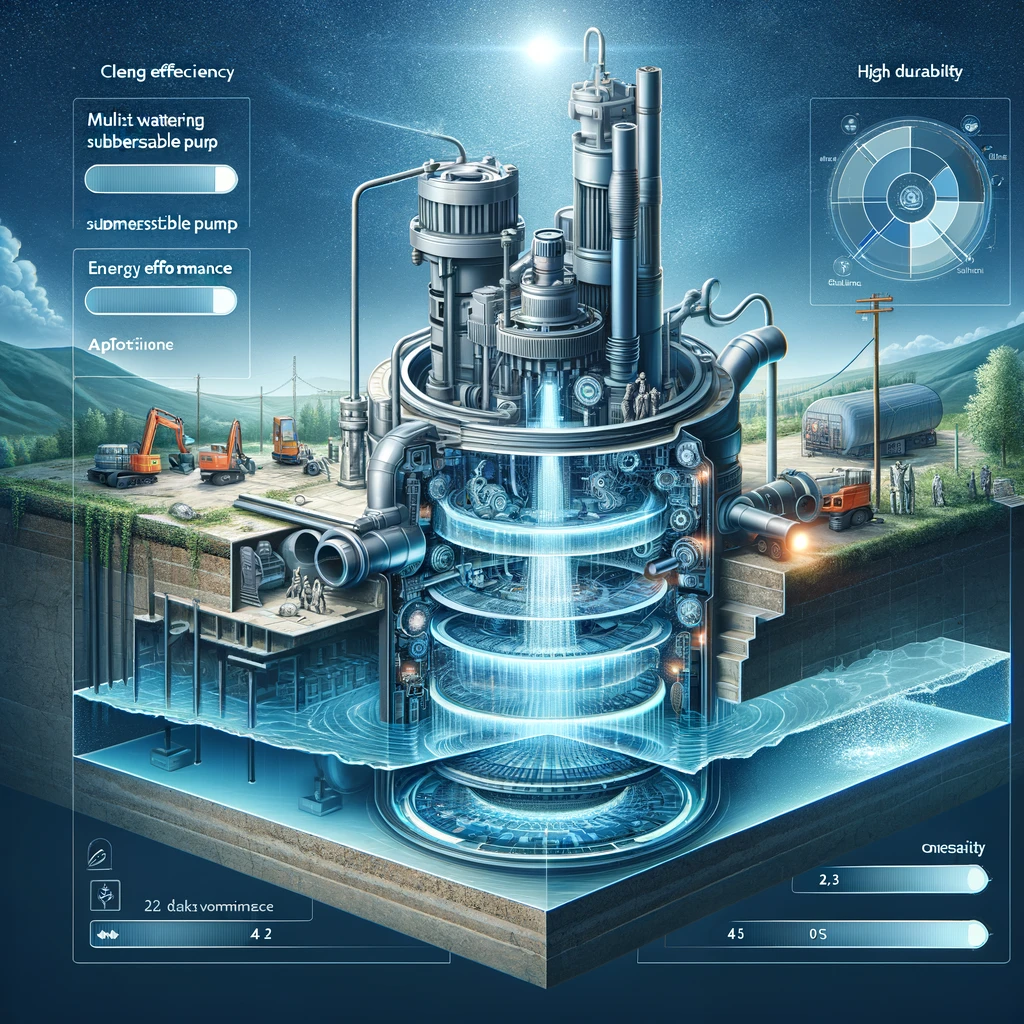

The Unveiling of Multi Stage HOMA Submersible Pumps

The unveiling of multi-stage HOMA submersible pumps brings numerous advantages to pump systems. With their efficiency, space-saving design, and ability to handle high pressure, these pumps provide flexibility in various applications. Additionally, their capability to handle solids makes them suitable for applications such as solid management in wastewater systems. The maintenance cost of multi-stage HOMA pumps is also relatively low, ensuring long-term durability. Overall, the benefits of using multi-stage HOMA submersible pumps are evident, making them a reliable choice for pumping needs.

Decoding Multi Stage HOMA Submersible Pumps

Advantages of using Multi-stage HOMA submersible pumps are numerous. These pumps are known for their efficiency and reliability, making them a popular choice for various applications. The price of Multi-stage HOMA submersible pumps may vary depending on the specific model and features. However, the benefits they provide outweigh the initial investment. Users have expressed positive comments about the performance and durability of these pumps. Multistage pumps use multiple impellers to increase the pressure and efficiency of the pumping process, which is a significant advantage of using Multi-stage HOMA submersible pumps.

Another advantage of using Multi-stage HOMA submersible pumps is their ability to handle high pressure. With each stage in the pump, the pressure is multiplied, allowing for efficient pumping even in challenging conditions. This makes them ideal for applications that require pumping water or other fluids over long distances or at high elevations. The multistage pump design ensures that the pressure is evenly distributed, maximizing the effectiveness of the pumping system. Overall, the use of Multi-stage HOMA submersible pumps offers significant benefits and advantages for a wide range of pumping needs.

Purpose of Using Multi Stage HOMA Submersible Pumps

Advantages of using Multi-stage HOMA submersible pumps are plenty. These pumps, consisting of multiple stages, offer enhanced performance and efficiency compared to single-stage pumps. With each stage, the pressure is increased, allowing for higher pumping capabilities. This is particularly beneficial in scenarios where a significant amount of pressure is required, such as in irrigation systems or industrial applications. The use of multi-stage pumps also ensures a consistent flow of water, which is essential for maintaining the efficiency and productivity of various processes. With the ability to handle solids and manage wastewater, multi-stage HOMA pumps are ideal partners in sectors like construction, mining, and municipal industries.

Multistage pumps bring a plethora of benefits to the table. Multistage pumps use centrifugal force to deliver water at higher pressures, making them ideal for applications that require pumping water to great heights or over long distances. With each stage, the pump increases the pressure, allowing for efficient water transfer. This makes multistage pumps a popular choice in high-rise buildings, fire-fighting systems, and water supply networks. The versatility of these pumps is further enhanced by their ability to handle different types of liquids, including corrosive substances. With their durability and reliability, multi-stage HOMA pumps are the perfect solution for various industries, ensuring smooth operations and optimal performance.

Mechanism and Efficiency of Multi Stage HOMA Pumps

Multi-Stage HOMA pumps are known for their efficient mechanism and performance. These pumps offer several advantages, making them a preferred choice for various applications. With their multi-stage design, these submersible pumps provide enhanced pressure capabilities, allowing for increased pumping efficiency. The use of multiple stages in these pumps allows for a higher total head and better resistance against cavitation. Additionally, the durability factor of Multi-Stage HOMA pumps ensures long-lasting operation and reduced maintenance costs. The installation process is also relatively easy, further adding to the benefits of using these pumps. Overall, the mechanism and efficiency of Multi-Stage HOMA pumps make them a reliable and cost-effective solution for pumping needs.

Functional Efficiency of Multi Stage HOMA Pumps

Advantages of using Multi-stage HOMA submersible pumps are plenty. With their functional efficiency, these pumps are ideal for various applications. Whether it’s pumping water for irrigation purposes in agricultural fields or supplying water for household needs, Multi-stage HOMA pumps deliver exceptional performance. These pumps are suitable for both domestic and commercial use, making them a versatile choice for different settings. The benefits of using Multi-stage HOMA submersible pumps are further amplified by their durability and low maintenance cost. With their contact details readily available, acquiring these pumps for your needs is just a call away. So, whether you need to water your garden cultivator or require submersible pump types for your specific requirements, consider the functional efficiency of Multi-stage HOMA pumps for a reliable and efficient solution.

Multistage pumps use a series of impellers to increase the pressure of fluid passing through them. With each stage, the pressure is gradually increased, resulting in a higher overall discharge pressure. This makes Multi-stage HOMA pumps highly efficient in pumping water over long distances or to higher elevations. The advantage of using Multi-stage HOMA submersible pumps is that they can handle a wide range of flow rates, making them suitable for various applications. With their functional efficiency, these pumps ensure smooth and consistent water supply, making them an ideal choice for industries, agriculture, and domestic use. So, if you’re looking for a pump that can handle high-pressure tasks with ease, consider the benefits of Multi-stage HOMA pumps for your pumping needs.

Energy Efficiency in Multi Stage HOMA Pumps

Multi-stage HOMA submersible pumps are known for their exceptional energy efficiency, making them a popular choice among industries and individuals alike. These pumps are designed with multiple stages, which allows them to deliver higher pressure and flow rates compared to single-stage pumps. This efficiency is achieved by dividing the total head requirement into several stages, with each stage contributing to the overall pressure gain. By utilizing the energy more effectively, multi-stage HOMA pumps minimize energy wastage and reduce operational costs, making them a sustainable choice for various applications.

One of the key advantages of using multi-stage HOMA submersible pumps is their ability to deliver high energy efficiency benefits. These pumps utilize a series of impellers, each working in conjunction with a diffuser to increase the pressure of the fluid being pumped. By dividing the pressure gain across multiple stages, the pump can achieve high efficiency levels even when pumping fluids at high heads. Additionally, multi-stage pumps offer the flexibility to operate at different flow rates, catering to varying demands of the application. With their energy-efficient design and versatile capabilities, multi-stage HOMA pumps provide a reliable and cost-effective solution for pumping needs across various industries.

Profound Pressure Capabilities and Flexibility

With their profound pressure capabilities and flexibility, multi-stage HOMA submersible pumps offer numerous advantages. These pumps are beneficial for sellers, power pump system manufacturers, cultivators, and various industries that rely on effective pumping systems. The team at HOMA products pump skid systems services resources understands the benefits of using multi-stage HOMA submersible pumps. These pumps utilize multiple stages to enhance their performance, making them ideal for high-pressure applications. By dividing the workload among multiple stages, these pumps can handle increased pressure and deliver exceptional pumping power. This flexibility allows them to adapt to different operating conditions, ensuring optimal performance and efficiency. Additionally, multi-stage pumps provide a significant benefit in situations where high pressure is required, such as irrigation systems, industrial processes, and wastewater management. Overall, the profound pressure capabilities and flexibility of multi-stage HOMA submersible pumps make them a valuable asset in various industries.

Handling Pressure with Multi Stage HOMA Pumps

With the advantages of using multi-stage HOMA submersible pumps, handling pressure becomes a breeze. These pumps are specifically designed to handle high pressure situations, making them ideal for applications where a powerful and consistent flow is required. The benefit of using multi-stage HOMA pumps lies in their ability to maintain a steady pressure throughout the entire pumping process. Whether it’s pumping water, slurry, or other liquids, these pumps ensure efficient and reliable performance, allowing for uninterrupted operations in various industries. When it comes to handling pressure, multi-stage HOMA pumps are the go-to solution for their unmatched performance and reliability.

Utilizing multi-stage pumps brings numerous benefits when it comes to handling pressure. The unique design of these pumps allows for increased pressure capabilities, making them highly efficient in delivering liquids over long distances or at high elevations. With each stage of the pump, the pressure is increased, resulting in improved performance and greater pumping efficiency. This feature is especially advantageous in applications where a significant amount of pressure is required, such as municipal water supply systems, irrigation projects, or industrial processes. The versatility and effectiveness of multi-stage HOMA pumps in handling pressure make them an ideal choice for any situation that demands reliable and efficient pumping.

Flexibility and Versatility of MultiStage HOMA Pumps

Multi-Stage HOMA pumps are known for their flexibility and versatility, making them a popular choice in various industries. The advantages of using Multi-Stage HOMA submersible pumps include their ability to handle different types of fluids and adjust to varying flow rates. These pumps can also be customized to meet specific requirements, allowing for greater efficiency and performance. With their compact design, Multi-Stage HOMA pumps take up less space, making them ideal for applications where space is limited. Additionally, these pumps are energy efficient, reducing operating costs and environmental impact. Multistage pumps are truly a versatile solution for pumping needs.

Another benefit of Multistage HOMA pumps is their ability to operate at different stages. The stages of a pump refer to the number of impellers within the pump, with each stage adding more pressure to the fluid. This feature allows the pump to achieve higher pressure levels, making it suitable for a wide range of applications. Whether it’s pumping water in a high-rise building or transferring liquids in industrial processes, Multistage pumps excel in delivering the required pressure. With their reliable and efficient performance, Multistage HOMA pumps prove to be an essential asset in various industries.

The Ability to Handle Solids of MultiStage HOMA Pumps

Multi-stage HOMA pumps are designed to handle solids efficiently, making them highly advantageous in various applications. These pumps have the ability to handle solids with ease, thanks to their unique construction and innovative design. Unlike traditional pumps, multi-stage HOMA pumps incorporate multiple stages, each equipped with impellers that effectively break down solids and prevent clogging. This ensures uninterrupted pumping operations and reduces maintenance requirements. The benefit of using multi-stage HOMA pumps in solid management is evident in their ability to handle a wide range of solid materials, including wastewater, sludge, and other industrial waste. With their versatile design, these pumps can effectively handle even large solids, making them a reliable choice for demanding applications. Furthermore, the multi-stage design increases the overall efficiency of the pumping process, optimizing energy consumption and reducing operational costs. Overall, the ability of multi-stage HOMA pumps to handle solids effectively provides significant benefits and is a guiding factor for industries seeking efficient and reliable solid management systems.

Understanding the Capacity to Handle Solids

Advantages of using Multi-stage HOMA submersible pumps extend beyond their ability to handle liquids. These pumps are highly efficient in managing solids, making them an excellent choice for wastewater applications. The multi-stage design of HOMA pumps allows them to effectively handle solid particles, such as soil or debris, without clogging the system. With the use of these pumps, industries like agriculture, construction, and john deere can benefit from improved pumping efficiency and reduced maintenance costs.

The benefits of using Multi-stage HOMA submersible pumps for solid management are manifold. With multiple stages, these pumps can effectively handle different types of solids, ranging from smaller particles to larger debris. The design of the pump ensures that solids are efficiently transported without causing blockages or disruptions in the pumping system. With the ability to handle solids, these multi-stage pumps are a preferred choice for various applications, including wastewater treatment plants, agriculture, and john deere. The reliability and durability of Multi-stage HOMA pumps paired with their solid-handling capabilities make them a valuable asset for any industry in need of efficient and effective pumping solutions.

Role of MultiStage Pumps in Solid Management

Multi-stage HOMA submersible pumps play a crucial role in solid management due to their unique advantages. These pumps are designed to handle various sizes and types of solids, making them highly versatile in different applications. With their multi-stage design, they provide efficient pumping of solids, ensuring effective solid management in various industries. The benefits of using multi-stage HOMA submersible pumps for solid management are numerous. These pumps offer higher efficiency and greater reliability compared to other pump types, resulting in reduced downtime and increased productivity. Additionally, multi-stage pumps can be customized to meet specific requirements, providing tailored solutions for solid management in different categories of industries. With the ability to handle solids of different sizes and types, multi-stage HOMA pumps are a reliable and efficient choice for solid management applications.

One of the main advantages of utilizing multi-stage HOMA submersible pumps is their ability to handle solids effectively. These pumps are specifically designed to handle solid particles present in the media being pumped, ensuring smooth operation without clogging or blockages. With their multi-stage configuration, these pumps can effectively handle solids of various sizes, ranging from small particles to larger debris. The multi-stage pump design enables efficient solid handling, preventing damage to the pump and ensuring uninterrupted operation. The use of multi-stage HOMA pumps in solid management provides a significant benefit in terms of reducing downtime and maintenance costs associated with pump failures due to solids accumulation. Overall, the ability of multi-stage HOMA pumps to handle solids efficiently makes them an ideal choice for solid management applications in various industries.

Maintenance Cost and Durability of MultiStage HOMA Pumps

The maintenance cost and durability of multi-stage HOMA pumps are key factors that set them apart from other submersible pumps. The advantages of using multi-stage HOMA submersible pumps include their ability to handle high pressures and efficiently pump fluids. These pumps are specifically designed for durability, with robust construction and high-quality materials ensuring long-lasting performance. By using multi-stage pumps, the benefits of increased efficiency and reduced energy consumption can be realized. Furthermore, with the ability to handle solids and withstand challenging environments, multi-stage HOMA pumps offer a reliable solution for various pumping applications. Maintenance costs are minimized due to the pumps’ durability and efficient operation, resulting in lower overall operational costs. In summary, the maintenance cost and durability of multi-stage HOMA pumps are important considerations when choosing a submersible pump, as these factors greatly contribute to the long-term benefits and reliability of the pumping system.

Breaking Down the Maintenance Cost

One of the key advantages of using Multi-stage HOMA submersible pumps is the cost-effective maintenance they offer. With each stage in the pump having its own impeller, the maintenance process becomes much simpler compared to single-stage pumps. This means that even beginners in water treatment or pump maintenance can easily handle the upkeep of Multi-stage HOMA pumps. The benefits of using Multi-stage HOMA submersible pumps extend beyond just simplified maintenance, as these pumps are known for their reliability, durability, and increased efficiency.

Multistage pumps use multiple impellers to generate higher pressure levels, offering significant benefits in terms of pumping efficiency and energy consumption. With each stage in the pump contributing to the overall pressure, the maintenance cost of Multi-stage HOMA pumps is further reduced. This is because the wear and tear are distributed among the different stages, prolonging the life of the pump components. Additionally, the durability factor of Multi-stage HOMA pumps ensures that they can handle the demanding conditions often encountered in water treatment processes. Overall, the lower maintenance cost and increased durability make Multi-stage HOMA pumps a cost-effective choice for various applications.

Durability Factor of Multi Stage HOMA Pumps

The durability factor of Multi-Stage HOMA pumps is a major advantage when considering the use of these submersible pumps. Multistage pumps are designed with multiple stages, each with its own impeller and diffuser, allowing for increased pressure and efficiency. With this design, Multi-Stage HOMA pumps are able to handle high-pressure applications with ease. Additionally, the materials used in the construction of these pumps are highly durable, ensuring long-lasting performance even under demanding conditions. This durability factor not only extends the lifespan of the pump but also reduces the need for frequent repairs or replacements, ultimately saving costs for the users.

One of the key benefits of using Multi-Stage HOMA submersible pumps is their ability to handle a wide range of applications. Multistage pumps are capable of pumping water, as well as other fluids, with high efficiency and reliability. With multiple impellers and diffusers, these pumps are able to generate high pressures, making them suitable for various industries and sectors. Whether it’s for industrial use, irrigation purposes, or wastewater management, Multi-Stage HOMA pumps offer a versatile solution. Their durability and ability to handle different fluids make them a cost-effective choice for businesses, ensuring efficient operations and reliable performance.

Installation Process of Multi Stage HOMA Pumps

The installation process of Multi-Stage HOMA Pumps is straightforward and convenient. The first step involves preparing the site by ensuring there is enough space for the equipment and that the area is free from any debris or obstructions. Next, the pump is carefully lowered into the water, ensuring that it is fully submerged. The benefit of using Multi-Stage HOMA submersible pumps is that they can efficiently pump water from deep depths, making them ideal for various applications such as irrigation, drainage, or wastewater management. With their multiple stages, these pumps are able to deliver high pressure, allowing for effective handling of water even in challenging environments. Additionally, the installation of Multi-Stage HOMA pumps offers the advantage of reducing energy consumption and minimizing maintenance requirements. Overall, the ease of installation and the numerous benefits of using Multi-Stage HOMA submersible pumps make them a reliable and efficient choice for pumping applications.

Easy Installation of Multi Stage HOMA Pumps

Installation of multi-stage HOMA pumps is incredibly easy and straightforward. One of the advantages of using multi-stage HOMA submersible pumps is their simple installation process. With clear instructions and user-friendly manuals, setting up these pumps is a breeze. These pumps come equipped with all the necessary components, making the installation process hassle-free and efficient. Whether you are a seasoned professional or a novice, you can easily install these pumps without any complications.

The benefits of using multi-stage HOMA pumps extend beyond their easy installation. These pumps are designed to handle a wide range of pumping requirements. With their multiple stages, they can efficiently handle high-pressure applications with ease. The versatility of multi-stage pumps allows them to handle various types of liquids, including those with solids. This flexibility makes them suitable for a wide range of industries and applications, including wastewater management, agriculture, and industrial processes. With their multiple stages, these pumps provide superior performance and efficiency, making them a reliable choice for all your pumping needs.

Considerations during HOMA Pump Installation

When considering the installation of HOMA pumps, there are several important factors to take into account. Firstly, it is crucial to understand the advantages of using multi-stage HOMA submersible pumps. These pumps offer numerous benefits, including increased efficiency and the ability to handle solids effectively. Additionally, multi-stage pumps use a series of stages, each with its own impeller, which allows for higher pressure and greater pumping capabilities. With this in mind, it is essential to carefully select the appropriate stage pumps based on the specific requirements of the project. The size and capacity of the pump should be considered in relation to the desired pumping capacity and the type of material being pumped.

Furthermore, the installation of HOMA pumps should also take into account the practical aspects of the project. The location of the pump should be strategically chosen to ensure easy access for maintenance and repairs. Additionally, considerations should be made regarding the connection of the pump to the desired system or equipment. Whether it is connecting the pump to a boomless tractor sprayer or incorporating the pump into a larger system, proper planning is key. It is also important to consider the color and design of the pump, as this can have a significant impact on its visibility and overall aesthetic appeal. By carefully considering these factors during HOMA pump installation, the efficiency and longevity of the system can be maximized.

FAQ

What are Multi-stage HOMA submersible pumps?

Multi-stage HOMA submersible pumps are a type of pump that is designed to be submerged in water and can operate at different stages or levels of pressure.

What is the purpose of using Multi-stage HOMA submersible pumps?

The purpose of using Multi-stage HOMA submersible pumps is to efficiently pump water from underground sources, such as wells or boreholes, to the surface for various applications.

How do Multi-stage HOMA pumps work and what is their efficiency?

Multi-stage HOMA pumps work by using multiple impellers that are stacked on top of each other to increase pressure and flow rate. This design allows for higher efficiency in pumping water compared to single-stage pumps.

What is the functional efficiency of Multi-stage HOMA pumps?

The functional efficiency of Multi-stage HOMA pumps refers to their ability to deliver water at high pressures and flow rates, making them suitable for applications that require strong water pressure, such as irrigation or water supply systems.

Are Multi-stage HOMA pumps energy-efficient?

Yes, Multi-stage HOMA pumps are energy-efficient due to their design that allows for increased pressure and flow rate without the need for excessive energy consumption.

Can Multi-stage HOMA pumps handle high pressure?

Yes, Multi-stage HOMA pumps have profound pressure capabilities, meaning they can generate and handle high levels of pressure efficiently.

Are Multi-stage HOMA pumps flexible in terms of pressure adjustment?

Yes, Multi-stage HOMA pumps offer flexibility in adjusting the pressure as per the specific requirements of the application, making them versatile for a wide range of uses.

Can Multi-stage HOMA pumps handle solids?

Yes, Multi-stage HOMA pumps have the ability to handle solids present in the water, such as sand or debris, without clogging or damaging the pump.

What is the role of Multi-stage HOMA pumps in solid management?

Multi-stage HOMA pumps play a crucial role in solid management by efficiently pumping water with solids, preventing blockages and maintaining a smooth flow.

What is the maintenance cost of Multi-stage HOMA pumps?

The maintenance cost of Multi-stage HOMA pumps is relatively low due to their robust construction and efficient design, resulting in less frequent repairs and replacements.

How durable are Multi-stage HOMA pumps?

Multi-stage HOMA pumps are known for their durability as they are built to withstand harsh environments and continuous operation, ensuring long-lasting performance.

Is the installation process of Multi-stage HOMA pumps easy?

Yes, the installation process of Multi-stage HOMA pumps is relatively easy as they are designed for submersion in water and come with clear instructions for installation.

What considerations should be taken during HOMA pump installation?

During HOMA pump installation, considerations such as the depth of the water source, electrical connections, and proper sealing should be taken into account to ensure proper functioning and longevity of the pump.