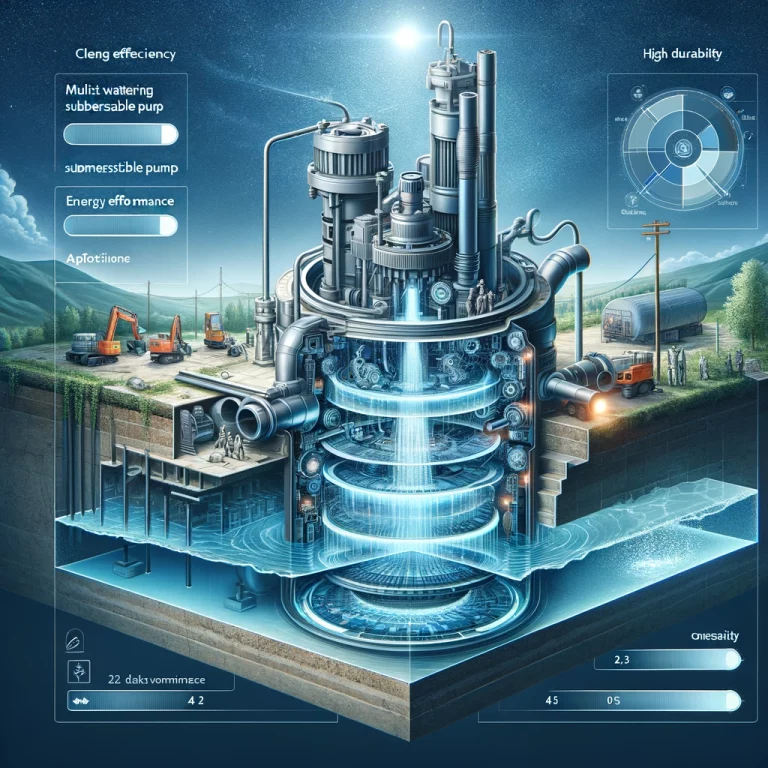

Features and specifications of low head HOMA submersible pumps

Understanding the Performance of Low Head HOMA Submersible Pumps

Low head HOMA submersible pumps are a critical component of various industries, including wastewater treatment plants and agricultural irrigation systems. Understanding the performance of these pumps is essential for maximizing their efficiency and ensuring optimal operation.

When it comes to low head applications, HOMA submersible pumps have proven to be highly reliable and efficient. These pumps are specifically designed to handle the challenges presented by low head conditions, where the vertical distance between the water source and the discharge point is relatively small. The performance of these pumps is measured by their ability to move water efficiently while overcoming the low head conditions. The key factors that contribute to the performance of HOMA submersible pumps in low head applications include their power consumption, flow rate, and head capacity. Additionally, factors such as the pump’s design, construction materials, and motor efficiency play a significant role in determining its overall performance. Understanding these factors is crucial for selecting the right pump for the specific low head application and ensuring optimal performance. In the next section, we will explore the efficiency of HOMA submersible pumps for low head applications, shedding light on how these pumps excel in delivering high performance while minimizing energy consumption.

Exploring the Efficiency of HOMA Submersible Pumps for Low Head Applications

HOMA submersible pumps have long been recognized for their efficiency and reliability in various applications. When it comes to low head applications, these pumps continue to demonstrate their exceptional performance. The term “low head” refers to situations where there is a minimal vertical distance between the water level and the discharge point. In such cases, it is crucial to have a pump that can efficiently move water without excessive energy consumption.

One of the key factors that contribute to the efficiency of HOMA submersible pumps for low head applications is their design. These pumps are specifically engineered to deliver optimal performance in low head situations. The impeller design and construction play a vital role in ensuring efficient water movement, enabling these pumps to operate effectively even with minimal head pressure. Additionally, the motor design of HOMA submersible pumps is expertly crafted to minimize energy loss and keep power consumption to a minimum. As a result, these pumps can deliver a high flow rate while utilizing less energy compared to other alternatives in low head applications.

Unveiling the Design and Construction of Low Head HOMA Submersible Pumps

When it comes to the design and construction of low head HOMA submersible pumps, there are several key factors that contribute to their efficiency and functionality. One important aspect is the selection of high-quality materials that are resistant to corrosion and wear. These pumps are typically made from durable materials such as stainless steel or cast iron, ensuring longevity and reliability in various operating conditions.

In terms of design, low head HOMA submersible pumps are specifically engineered to handle low water levels and operate effectively in shallow applications. They are equipped with a compact structure and a slim profile, allowing for easy installation and maintenance in limited spaces. Additionally, these pumps are designed with a high-efficiency hydraulic system, which enables them to deliver optimal performance while consuming less energy. Overall, the combination of robust construction and thoughtful design makes low head HOMA submersible pumps a reliable choice for low head operations.

The Advantages of Using Low Head HOMA Submersible Pumps

Low head HOMA submersible pumps offer several advantages for various applications. One key advantage is their energy efficiency. These pumps are specifically designed to operate at low head conditions, which means they are optimized to deliver high performance while consuming minimal energy. This not only helps in reducing electricity costs but also contributes to environmental sustainability by minimizing energy consumption. Additionally, low head HOMA submersible pumps are known for their high efficiency motor design and advanced hydraulic features, ensuring efficient water movement and delivery.

Another advantage of using low head HOMA submersible pumps is their robust construction and durability. These pumps are built to withstand demanding conditions and extended service life. The use of high-quality materials and precision engineering ensures that they can handle continuous operation without any compromise in performance. Moreover, their submersible design allows them to be submerged in water, protecting them from external elements, such as moisture, dust, and corrosive substances. This enhances the overall reliability and longevity of the pumps, making them a cost-effective investment in the long run.

A Closer Look at the Functionality of HOMA Submersible Pumps for Low Head Operations

HOMA submersible pumps have gained recognition in the field of low head operations due to their exceptional functionality and reliability. These pumps are specifically designed to operate efficiently in applications where there is a minimal difference in water levels or head. Low head operations typically involve water transfer or drainage tasks in situations such as wastewater treatment plants, industrial processes, or agricultural irrigation systems.

One of the key features of HOMA submersible pumps that contribute to their functionality in low head operations is their innovative design. These pumps are equipped with impellers that are optimized for low head applications, ensuring effective water flow even in scenarios with minimal pressure differences. Additionally, the construction of the pump housing and the materials used ensure the pumps’ longevity and resistance to corrosion, making them suitable for prolonged use in diverse environments. This combination of design and construction elements allows HOMA submersible pumps to deliver superior performance and reliability when operating in low head conditions.